After a long time proved easy with steel for modern passenger vehicles, the Steel Market Development Institute is slightly changing the melody for a future of Autonomous, Connected, Electric and Shared vehicles. In a presentation to the International Motor Press Association, SMDI conceded that although weight on an isolated basis affects driving range and cannot be ignored, the overall impact on the viability of ACES designs isn’t necessarily the same, along with other qualities can be even much more important. And the bottom line on range versus cost is likely to be a wash, said SDMI VP Dr. Jody Hall.

With regards to materials selection, weight can fall to second place when the vehicle’s environment changes, and for ACES vehicles, the main concern is safety, especially for vehicles where the occupants might not necessarily be seated in an ideal position. Shuttle service automated vehicles, for instance, pose a wide range of safety concerns. To easily accommodate the entrance of all kinds of passengers, a wide opening is desirable, and that raises vehicle B pillar design concerns. The steel industry has been developing slide open\/closed doors that when closed will latch into a bodyside ring, similar to an approach once used in utility vehicles, to meet regulatory side impact requirements.

Inside there’s no sensible way to ensure passengers are buckled up, so even when the vehicle is limited to low speed operation, the additional strength of an all steel structure improves its crashworthiness. ACES vehicle operation relies upon a broad range of inputs from external sources to its typically surface mounted sensors and cameras, processed by electronic control units to onboard actuators. Even though any input device that is mounted on or close to an external surface has exposure to harm, SMDI said the greater strength of a steel car made it safer in an accident. SMDI also cited data from ArcelorMittal, a diversified steel company, in its presentation.

Aluminum became the material of choice for electric vehicles battery packs in all premium models.

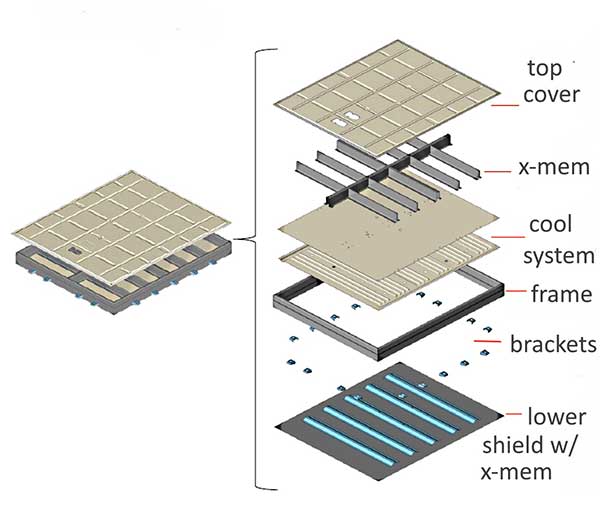

Nevertheless, SMDI pointed to ArcelorMittal’s steel based battery pack carrier that weighs inside ten percent of the aluminium design and for which it projects a per vehicle saving of $120. The modular design of the tray includes an upper and lower crossmembers, with the lower one integrated with the bottom cover. The liquid temperature regulation system is centrally based in the structure, all components incorporate various high strengths steels.

The modest weight charge of the steel battery provider will be conquered in the upcoming generation of lithium-ion batteries, Ram Ilyer of ArcelorMittal R&D said. He compared an Audi e-tron with its 70% steel body and aluminum doors and other panels with a Jaguar I-Pace and its mainly aluminum building and construction: the 2 cars are rather different size and the Audi has a 95-kWh battery pack, vs. a 90-kWh pack for the IPace, so computation adjustments were produced the difference in footprint. Presuming an aluminum rate premium of $5 kg, the cost of going aluminum on the e-tron was predicted to be $853, whereas adding battery capability to conquer the additional weight of steel in the Audi, based upon a 2020 cost of $170 kWh, would be $850, successfully the same.

Presuming continued decreases in battery rates, SMDI asserted that including battery should soon be less pricey than an aluminum-intensive lorry style.

Read other article on SAE-UK, shop safety Auto Parts products and replacement 9005 led bulbs from one of our 17,000 SAE membership for routine maintenance and repairs. For more information on diagnosing and repairing car light problems, chat with a knowledgeable expert at LedoAuto.