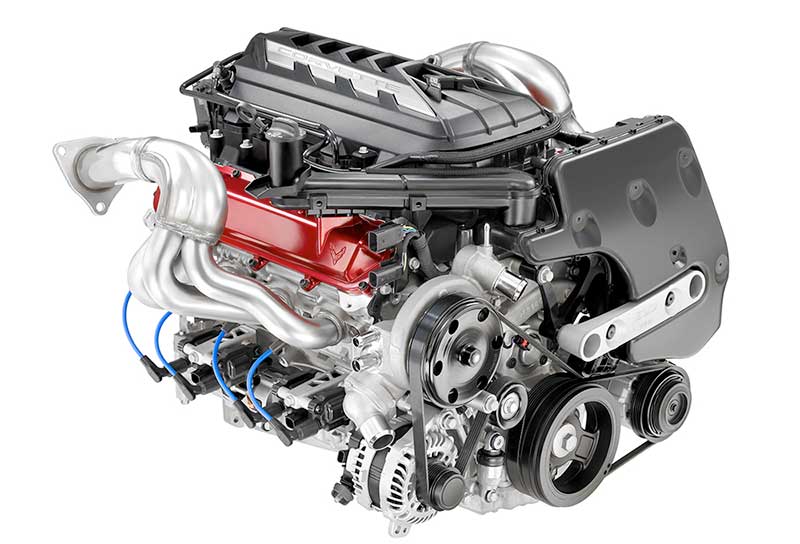

GM‘s new LT2 5th generation small block V8 can have roots that extend to 1955, however, it brings an extensive list of new functions for the party. Its aluminum block has revised oiling and venting arrangements in support of a dry sump lubrication system with one pressure and 3 scavenge pumps. The cast iron is shallower to allow the mounting of the motor 1 in. Lower in the vehicle versus C7. The crankshaft nose is longer, to power revised accessory drives. There is an oil tank fitted in the upper left corner of the engine and the oil cooler’s capacity is 25% greater than in C7 for more dependable operation during extreme conditions.

More aggressive valve timing and 11.5: 1 compression together with new intake and exhaust manifolds raise output to a SAE rated 490-495 hp at 6450 rpm. Peak torque is rated at 465-470 lb-ft at 5150 rpm. The LT2 is redlined at 6500 rpm. Cylinder deactivation remains to help enhance fuel economy. Asked what kept GM from clearing a decent 500 horsepower hurdle for the 6.2-L LT2, admitted Jordan Lee, global chief engineer for small block engines, Honesty stopped us at a level that we were confident might be provided in all the engines we will build for the new Corvette.

DCT is an Excellent Performance Solution.

As the only naturally aspirated V8 in the segment, this engine will deliver the visceral experience expected of a Corvette, he told Automotive Engineering at the unveiling of the car in Tustin, California. Tremec will provide a U.S.-made 8 speed dual clutch automated manual transmission with pallet change control. With lack of clutch pedal, the usual gear lever is also a thing of the Corvette’s past. Instead, two console mounted pull toggles select Drive or Reverse while three buttons choose either Park, Neutral, or the Low\/Manual modes. Executive chief engineer Tadge Juechter added, Irrespective of driving mode, our performance change algorithms are so driver focused they can sense spirited driving and maintain lower gears longer for optimal acceleration.

Explaining the loss of a mechanical gearbox chosen by 20% of C7 buyers, Juechter noted, With no interruption of torque delivery during upshifts, the DCT is an excellent performance solution. Squeezing a clutch pedal in the foot box and shift linkage down the structural center tunnel would have posed design compromises we were not prepared to make. And we know our clients will be thrilled with the sub-3 second zero-to-60 option. To exploit the advantages of a mid engine car’s enhanced traction at the rear wheels, first gear ensures greater torque multiplication, while 7th and 8th are tall overdrive ratios for a quiet and efficient highway cruising. The middle five gear ratios are tightly spaced for optimal acceleration and track performance. As a race car, the transaxle’s input shaft is placed underneath half shaft to facilitate mounting the engine lower in the vehicle. Electronic traction management and limited slip differential controls are available.

In addition to previous Weather, Tour, Sport and Track driving modes, 2 additional options have actually been added to C8. MyMode is a configurable setting, and “Z mode” surpasses MyMode to allow tuning of up to twelve engine, transmission, steering and damper efficiency variables.

Read another article on SAE-UK, shop safety Auto Parts products and h8 bulb led replacement from one of our 17,000 SAE membership for routine maintenance and repairs. For more information on diagnosing and repairing car light problems, chat with a knowledgeable expert at SAE membership supplier.