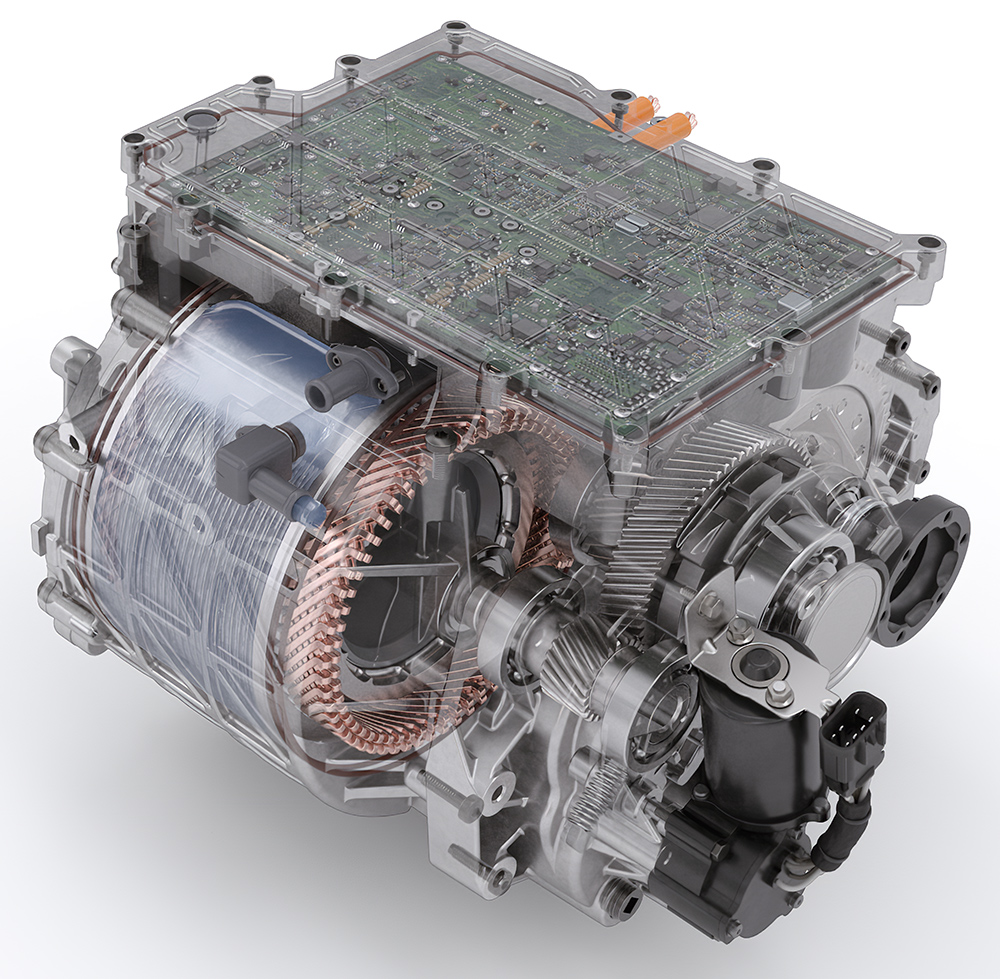

BorgWarner’s new integrated Drive Module (iDM – left), currently in development, takes key propulsion-system elements for electrified vehicles and bundles those into a self-contained package. Comprised of an electric motor, transmission, power electronics and motor controller/inverter, the iDM system could reach the global market as early as the 2021 model year.

“We’re packaging into one system all of the individual modules that work together to form an electric vehicle’s powertrain, and that level of integration means optimized weight, cost and package size with an added NVH benefit,” said David Fulton, BorgWarner’s Director of Electric Machines Innovations Group and Power Drive Systems.

Fulton and others spoke with Automotive Engineering during a recent media program at BorgWarner’s Propulsion Technical Center in Auburn Hills, Michigan. “We’re currently building proof-of-concept iDM samples. Those samples will be used for performance and efficiency mapping in 2019,” Fulton said.

With the inverter located atop the motor and transmission, that enclosed package acts as an additional brace to stiffen the iDM assembly. “That’s important as you don’t want to excite the natural frequencies associated with the motor’s operating modes as those frequencies can cause unwanted humming or whines,” Fulton (with the iDM, right) explained.

Electrified propulsion systems currently in production need cooling hoses for both the electric drive module and the inverter. “With the iDM, you get rid of one set of cooling hoses by combining the input and output connections,” he said. BorgWarner’s electric Drive Module (eDM) integrates its patented high-voltage hairpin (HVH) electric motor with the eGearDrive transmission. The eDM debuted on the 2018 C30 four-door electric car produced by China’s Great Wall Motors.

“With the [Sept. 2017] acquisition of U.K.-based Sevcon Inc., we gained power-electronics capability and that is enabling us to evolve to the iDM,” Fulton said. Preliminary specifications for the iDM include an operating voltage of 250-450 Vdc; continuous power at the wheels of 55 kW at 330 Vdc; peak power at the wheels of 125 kW at 330 Vdc; continuous torque at the wheels of 1200 Nm; and peak torque at the wheels of 2800 Nm.

“We can do different adjustments with the gear ratio and with the motor to change those numbers and put the efficiency sweet spot where the customer would like it,” said Fulton. BorgWarner estimates that by 2023, its electrified propulsion products will be on half of the hybrid-electric vehicles and approximately one-third of the EVs produced globally.

Article source: https://www.sae.org/news/2018/11/borgwarner-idm-testing